sheet metal drawing operation is used to make

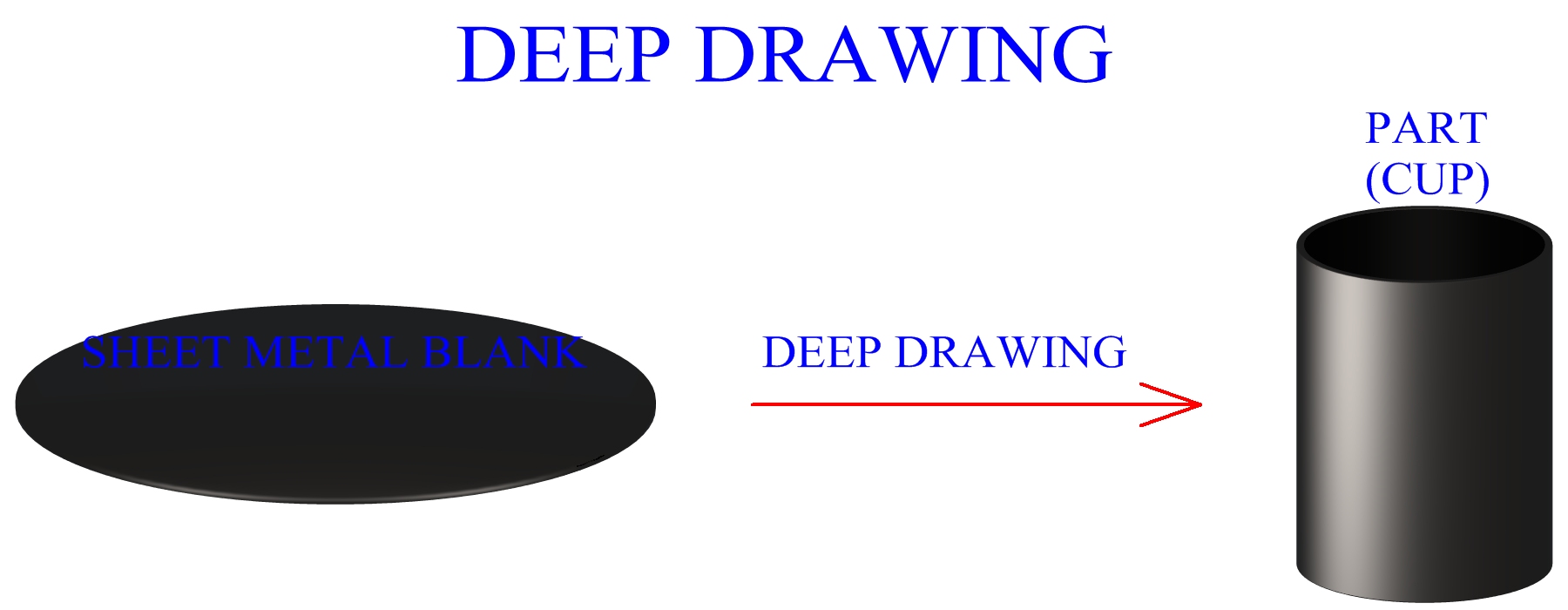

Most of the utensils used in the kitchen. H cup height.

Sheet Metal Forming Processes And Equipment Machinemfg

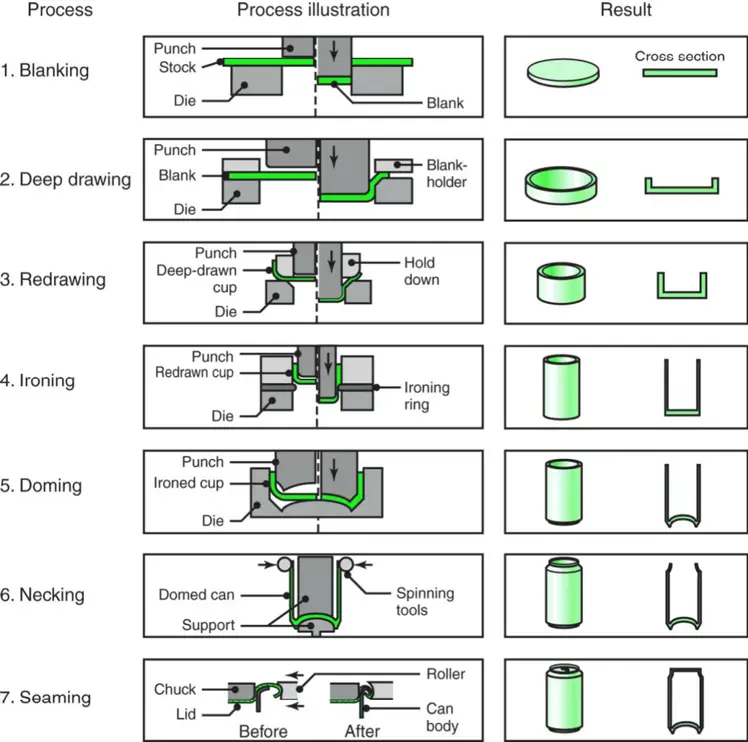

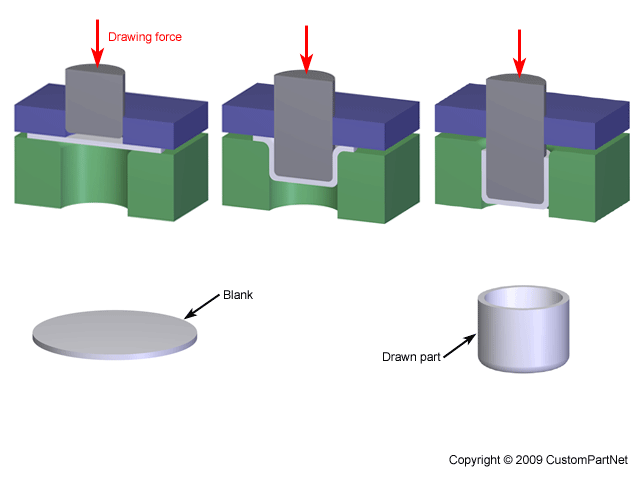

It is a Sheet Metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

. Wildcat2199 is waiting for your help. Cutting operation Plastic deformation Penetration 13 thickness Fracture Shearing. 1 Deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base.

Stretch forming is a sheet metal forming process in which the sheet metal is intentionally stretched and simultaneously bent to have the shape change. Beverage cans ammunition shells automobile body panels. Thickness of sheet metal t 3 mm.

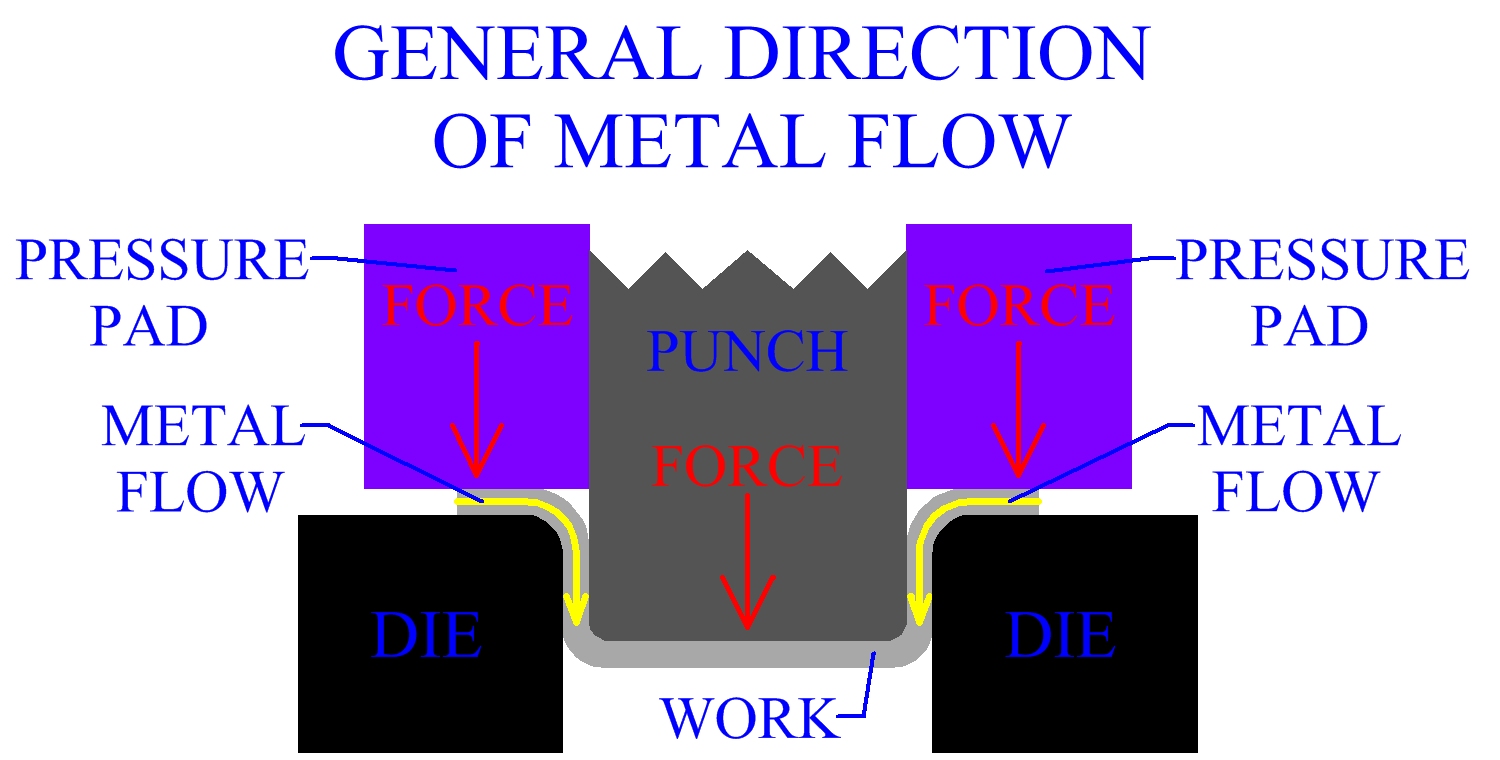

For deep drawing the sheet is drawn radially over the surface of the die by a punch. D cup diameter. Sheet is held by jaws or drawbeads at both the ends and then stretched by punch such.

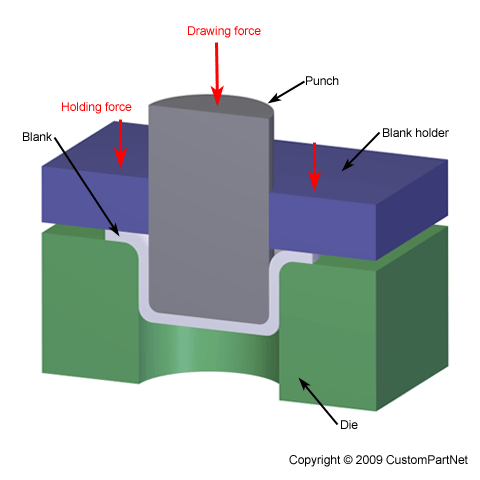

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. Sheet metal is one of the very convenient ways that is used in metal working and it can be mended and cut into various shapes and dimensions. Drawing is classified into two types.

Where D blank diameter. Two main factors will cause the punch in deep drawing to draw the metal into the die cavity rather than shearing it. The blank is held down flat against the die by a blank holder 25.

Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Using a machine called power shear or square shear. Sheet metal drawing and wire bar and tube drawing.

When sheet metal is deformed by applying a force to get a required shape is termed forming. It may be appreciated that the type of. Using the right amount of pressure is essential to sheet metal drawing as it affects the metals size.

For making a pattern of holes or slots the sheet metal needs to be fabricated or punched. Define drawing in the context of sheet metalworking. Place the sheet metal workpiece against V-Die.

Add your answer and earn points. To shape the flat sheet metal variety of operations are performed on it. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved hollow parts.

As mentioned the punch and die setup is somewhat similar to a sheet metal cutting operation such as punching or blanking. Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a punch to push the metal into the cavity. Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die cavity and then pushing the metal into the opening with a punch.

Sheet metal drawing is defined as a plastic deformation over a curved axis. Deep drawing is a sheet metal forming process that involves complex material flow and force distributions. Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plasticAs the metal is drawn pulled it stretches to become thinner to achieve a desired shape and thickness.

A True or b false. Metal stamping is a cold-forming process that makes use of dies and stamping presses to transform sheet metal into different shapes. Drawing is a sheet metalworking operation used to produce cup-shaped or box-shaped or other complex-curved an concave parts.

I Determining blank diameter Now height to diameter ratio of cup ie. As you may have guessed sheet metal drawing is used to produce sheet metal. Deep drawing is mainly used for producing Cup-shaped components.

The more pressure applied the thinner the sheet. Sheet metal punch bends the workpiece up to the punch angle to compensate for the impact of spring-back. The punch angle is always less than the die angle.

A wide range of products are manufactured with the use of sheet metal making it an essential part of the modern world. Initially there is plastic deformation at. It is performed by placing a piece of sheet metal over a die cavity and then pushing the sheet into the opening with a punch.

Sheet Metal Drawing. With the use of the industrial manufacturing process sheet metal is formed by working metal into flat and thin pieces. I Number of draws.

The sheet is supported over die surface by a pressure ring which bears on the upper surface of the sheet thus preventing wrinkling of the metal while it is being drawn. The removed material is known as blank. Answer 1 of 4.

90 V-die and 88 angle punch are required. H dp 05 h d p 05. This is a metal forming process by which you can remove the material from the primary sheet of metal.

Drawing is a metalworking process which uses tensile forces to stretch metal or glass. Deep Drawing Deep Drawing is a sheet metal forming operation used to make cup-shaped box-shaped or other complex-curved hollow-shaped parts. Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch.

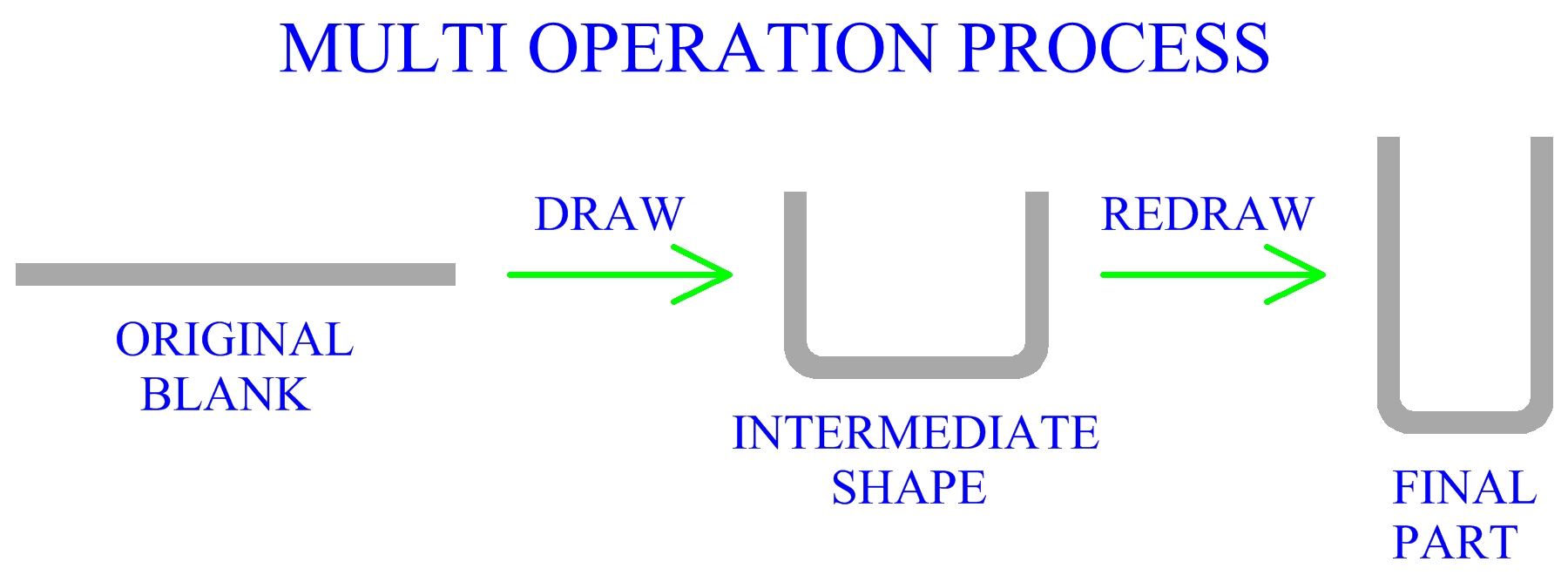

Blanking shearing a closed outline desired part called blank Punching sheared part is slag or scrap and remaining stock is a desired part. Ii Diameter at different stages of redraw. Define drawing in the context of sheet metalworking.

In sheet metal working the sheet metal is placed between punch and die. A pressure pad from bottom exerts pressure on the base of the drawn component. Pieces of flat sheet metal typically referred to as blanks are fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape.

Punch is pressed against the sheet metal. True False Coining is a bulk deformation process also used in sheet-metal work in which fine details in a die are impressed into the. While pressure is applied to the blank the drawing machine stretches the metal to the desired size and shape.

2 It is combination of metal forming process sheet metal process. As the metal is drawn pulled it stretches thinner into a desired s. 3 If the ratio of height to diameter of the product is greater than 05 then this drawing operation is known as deep drawing.

For example to bend a sheet metal part at a 90 angle.

Sheet Metal Tools Cutting Marking Bending Tools

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming An Overview Sciencedirect Topics

Virtual Lab Dayalbagh Educational Institute

Deep Drawing An Overview Sciencedirect Topics

Types Of Drawing Process Wire Drawing Rod Drawing And Tube Drawing Mech4study

What Is Deep Drawing Process Mech4study

Deep Drawing Find Suppliers Processes Material

Pin On Manufacturing Technology

9 Different Types Of Sheet Metal Operations With Diagram Pdf